Screen Deck Liners from BSC – Ultimate Protection from Abrasion

Description

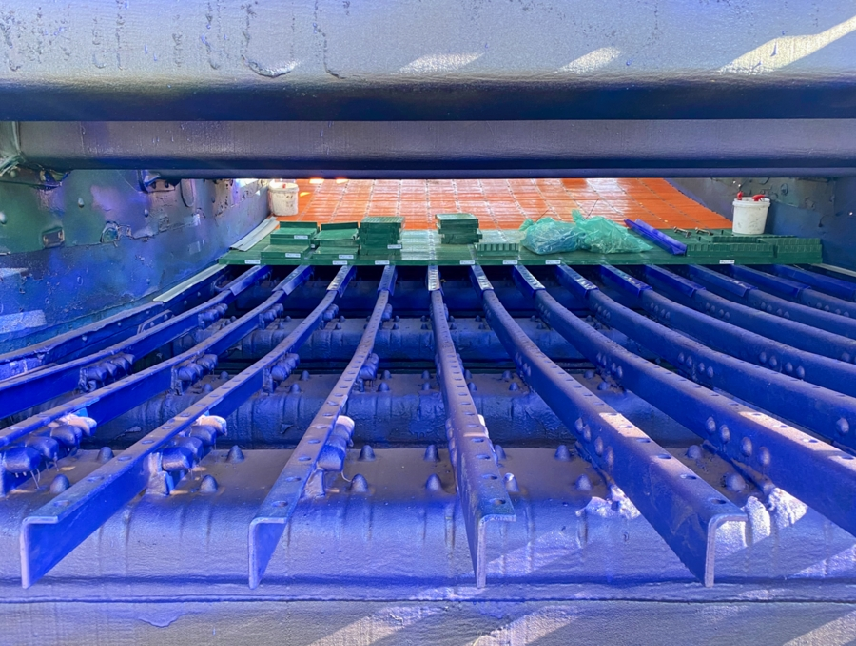

Vibrating Screens are widely used in mineral processing to separate out smaller particles from ore or slurry, however failure of the screen deck liner allows abrasion and corrosion to cause premature damage.

The Challenges

The BSC Solution for a Screen Deck Liner

BSC expert teams have sprayed a tough screen deck liner into hundreds of new, and in-service screens and screen parts (rails, excitor beams etc). This can be fast-set Nukote ST pure polyurea or HAR high abrasion resistance modified polyurea.

Nukote ST combines very good chemical and abrasion resistance with flexibility and low moisture vapour permeability. Very high abrasion resistant Nukote HAR can be used in some applications or very high wear zones. A composite two colour coat can be applied to provide a wear indicator for maintenance staff.

Nukote polyurea is applied in a single coating, with the thickness of screen deck liner increased in high wear zones. Nukote is touch dry within seconds at all temperatures and can be returned to full service within 24 hours.

Screens can be lined on-site or at our premises.

Key Nukote HTD Physical Properties

Elongation

350% ± 50% at break

Tensile Strength

20.7 ± 1.4 MPa

Hardness

50 ± 5 Shore D

100% solids

0% VOC

Abrasion Resistance

<1mg loss, Taber CS 17 Wheel, 1 kg/1000 rev

For Nukote lining solutions for mining projects,

contact BSC for more information.