Trommel Liners from BSC – Outperforms Rubber and Polyurethane

Description

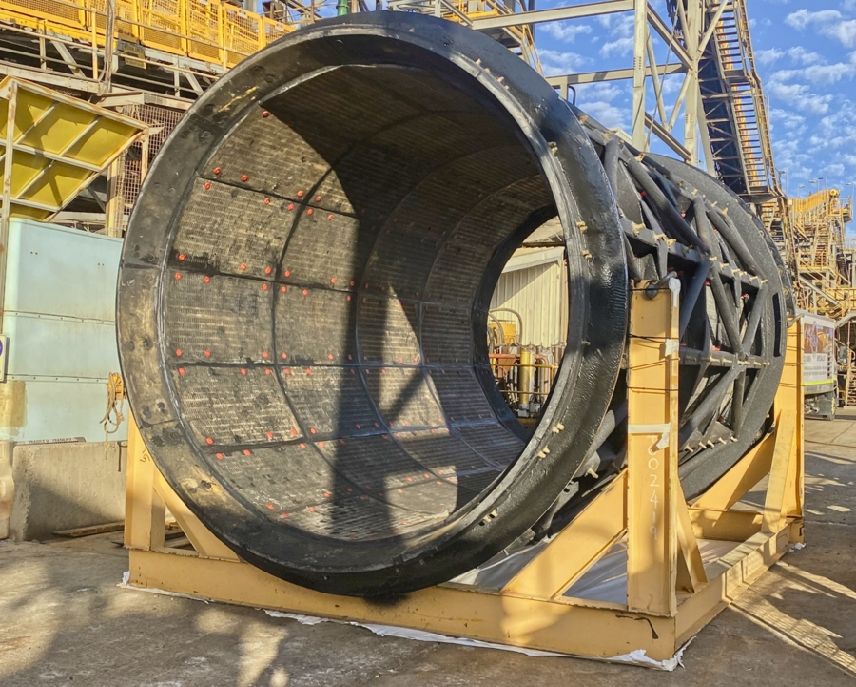

Trommels are bolted to the output end of mills and act as giant sieves to separate out the finely ground ore slurry.

They are rotating steel cylindrical cages, fitted with screens over a liner. Trommel liners have traditionally been rubber however polyurethane and polyurea have become the materials of choice.

The Challenges

The BSC Solution for Trommel Liners

BSC expert teams have sprayed hundreds of trommel liners with fast curing, flexible, and resilient Nukote polyurea and hybrid polyurea.

The old coating is removed with ultra high pressure water jetting. Following inspection and steel repairs, the surfaces are decontaminated and profiled ready for coating. Nukote HAR hybrid polyurea is then applied as a monolithic coating. Nukote HAR is specially selected for its extreme resistance to wear from abrasive slurries. Where steel has been partly worn away, this can be filled in with repair material or sprayed with extra polyurea. A two colour system can be applied to provide a wear indicator to maintenance staff.

Trommels can be lined on-site or at our workshops.

Clients report a longer service life and less on-line repairs for Nukote HAR lined trommels.

Key Nukote HAR Physical Properties

Elongation

275% ± 50% at break

Tensile Strength

22 ± 2 MPa

Hardness

42 ± 3 Shore D

Abrasion Resistance

<1mg loss, Taber CS 17 Wheel, 1 kg/1000 rev

For Nukote lining solutions for mining projects,

contact BSC for more information.